The Gripster 2.0 is a product that just makes sense once you see it in action. The device is like a portable version of the hang boards climbers use to train their fingers to support their body weight. You can use it for farmers carries, one arm deadlifts and to train for ring lifts. Because it’s got multiple surfaces, you can train pinch and supporting grip with one tool. That makes it a potential game changer. Find out about the journey to bring this idea to market with Gripster inventor Mike White.

Why Do We Need The Gripster?

Quick anatomy lesson. There are no muscles in the fingers. Flexion of the fingers and wrist is produced by the muscles of the forearm that originate from the medial (inside) elbow and terminate via long tendons that attach to the middle and end bone of each finger. (Horst 2008) Those tendons pass through what White calls an eyelet similar to the line on a fishing rod and that’s the area of vulnerability. “A lot of climbers get what’s called a pulley injury where they rip that eyelet off the bone,” explains White.

Because training for climbing often involves supporting your body weight on just a few fingers at a time, the ligaments and tendons are always doing overload work. Picture squatting your one rep max to competition depth for multiple sets and repetitions every time you train. Most strength coaches would tell you that’s a recipe for injury and the same is the case here.

Advantages of The Gripster Over a Hangboard

While climbers will continue to use hangboards, the Gripster 2.0 serves three important functions:

- You can use it right away

- Reduced strain on the shoulder

- Incremental loading

“They tell you when you first start climbing that you shouldn’t do any hangboard training for at least two years. You’ve got to spend that two years conditioning your ligaments to get stronger. So then when you go onto a hangboard you don’t give yourself pulley injuries,” he said. The Gripster, when used correctly can be part of that process of slowly conditioning your ligaments.

“They tell you when you first start climbing that you shouldn’t do any hangboard training for at least two years. You’ve got to spend that two years conditioning your ligaments to get stronger. So then when you go onto a hangboard you don’t give yourself pulley injuries,” he said. The Gripster, when used correctly can be part of that process of slowly conditioning your ligaments.

Another advantage of the Gripster over a hangboard is you can train your fingers without having your shoulder in extension. White says that this aspect of using the Gripster has even added to the climbers lexicon. “A lot of guys are talking about it on Reddit and what they’re doing is something they’re calling nohangs where they load the Gripster up on the floor.” Nohangs training or what strength athletes might call static holds, means reduced load on the shoulder which is already getting a ton of work in other training. “A lot of climbers get shoulder impingement, rotator cuff injuries because they’re spending their time with their arms overhead and their shoulders in extension,” White said.

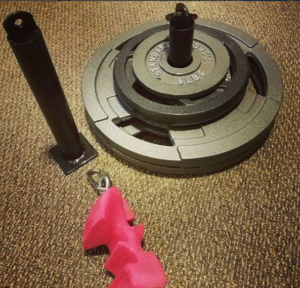

The gamechanging aspect of the Gripster is the ability to use incremental loading. Rather than standing on a crate or box to take load off the way climbers do with a hangboard, the Gripster allows you to be precise in your loading. “You can attach it to a pulley at the gym or use a loading pin to step the weight up by ten or twenty pounds as you get stronger,” says White.

Inventing The Gripster

A ten year climbing veteran, White says that his enthusiasm for climbing led him to start tinkering with what would become the Gripster.

“The Gripster started out as an idea something like a campus board panel with an eye bolt at the top. I connected it into the cable pulley machine at the gym, it was fun for messing around with but I soon discovered that balance was a major issue,” White said. White eventually decided to copy the same polyurethane technology used in climbing holds. This helps keep the texture consistent with what climbers will face on walls and improves durability.

“I took this over to a climbing holds fabricator and he said, ‘Oh man! When I show this to my boss he’s going to ask why I didn’t think of this!” White recalls. The future for the Gripster brand of products looks bright as doors to applications outside the climbing world are starting to appear.

Applications for Other Sports

“A lot of my customers are climbers but there is an opening in the market because of American Ninja Warrior,” he said. Grip sport and Jiu jitsu athletes are also seeing the applications for their training. Holding a gi, or training the pinch grip and ring deadlift could all be done with a single product. “A guy contacted me and said he’s won the North American Grip competition three years in a row and he’s interested in doing a review of the product,” White said.

Bumps In The Road

As you might imagine, the journey to make the Gripster a reality involved learning several new skills. “I went over to TechShop and did a few classes, I learned how to use the 3D scanner, the CNC router and the laser printer,” White said, adding that his background in 3D modeling for a game on the Playstation 3 platform was helpful in cutting down on his learning curve. “It was like this obsessive thing where the more I did it, the more I started learning. I’m editing video and publishing video, then I’m building a website, then I’m building an e-commerce website,” he said.

router and the laser printer,” White said, adding that his background in 3D modeling for a game on the Playstation 3 platform was helpful in cutting down on his learning curve. “It was like this obsessive thing where the more I did it, the more I started learning. I’m editing video and publishing video, then I’m building a website, then I’m building an e-commerce website,” he said.

White also remembers coming home from vacation to find that his fabricator hadn’t done any work. “I got all of these orders on Indiegogo and he promised that he would make them. I called in to check and he hadn’t done any work. I kind of flipped out because I had of all these customers that were waiting so as a consolation he said, ‘Well you can use my workshop.”

White says he ended up camping out in his van in a parking lot so he could work 12 hours a day to fill those initial orders that were his initial source of funds.

Financial Hurdles

“At the moment in terms of the product and the business side, the marketing isn’t a problem. The problem is I make them all myself and I can only make them so fast,” White said. This is related to funding. Money from Gripster’s Indiegogo campaign helped but didn’t put the company in a position to hire a fabricator. “It wasn’t enough to outsource the fabrication to other countries where it would be cheaper but it was enough to buy all of the materials.”

He’s currently in talks with a fabricator but until that piece of the puzzle is dialed in, customers are looking at a fourteen day potential turnaround for each order.

At the same time there’s the international shipping puzzle to contend with. “You buy it on the website and it’s $54.95 and to some countries, shipping works out to about $50 so I’ve really got to find distributors in other countries and get it into retail outlets then that’s when I can really push the marketing and advertising.

These problems aside, White has no regrets about how he started his entrepreneurial journey.

Burn The Boats

“The biggest thing that holds people back is their fear. It won’t work; someone else will steal the idea. The people who are successful are successful because they put their heart into it. You’ve got to burn your boats, because when you’re 95 in your hospital bed dying, you’re not going to think, ‘Gee I’m glad that I kept that full-time job and paid all of my bills’ you’re going to think ‘Why didn’t I do what I was inspired to do?’,” he said.